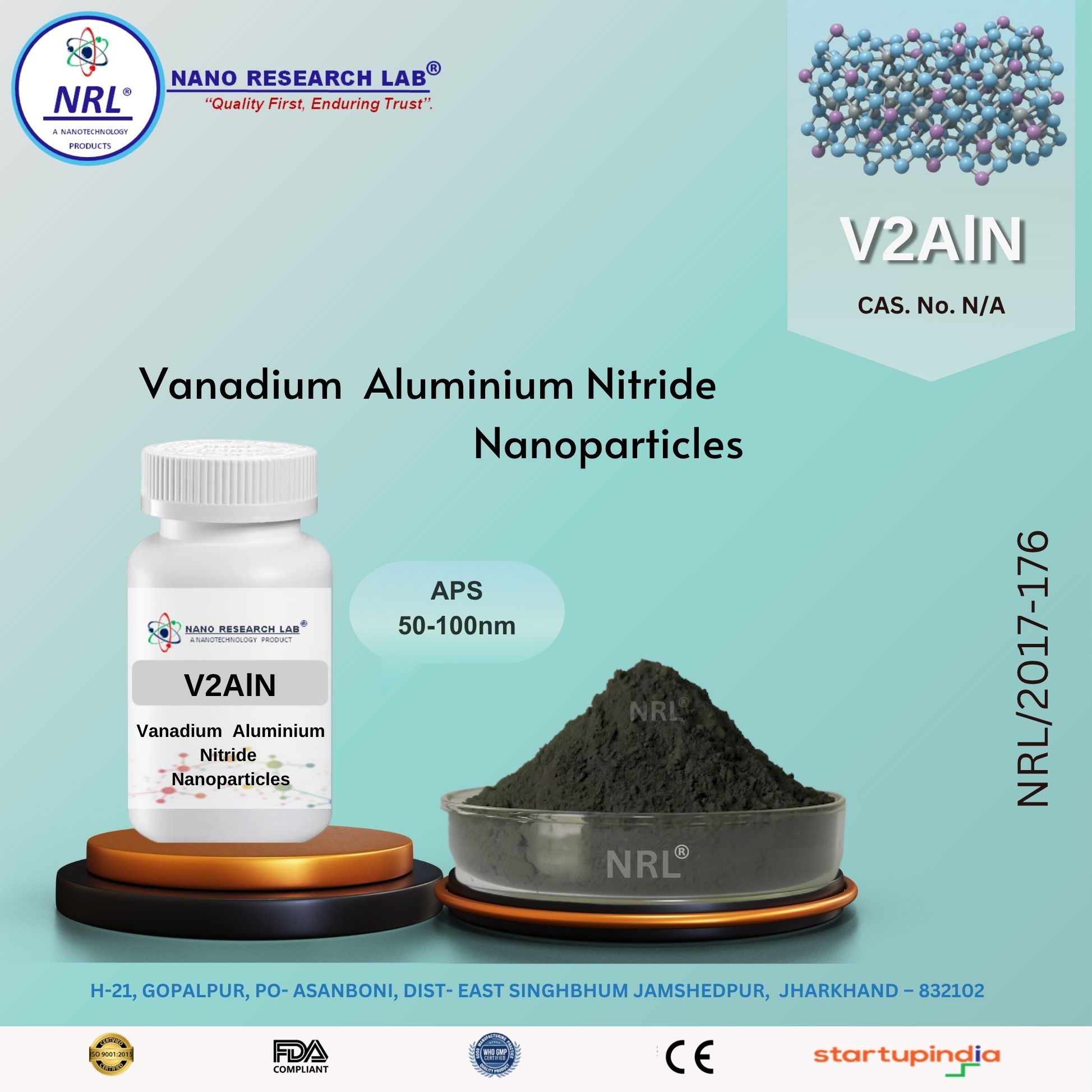

Vanadium Aluminium Nitride Nanoparticles / Nanopowder (V₂AlN, 50–100 nm, Purity >99%)

₹4500.00

🧪 Vanadium Aluminium Nitride Nanoparticles / Nanopowder

(V₂AlN, 50–100 nm, Purity >99%)

TECHNICAL DATA SHEET (TDS)

Vanadium Aluminium Nitride Nanoparticles / Nanopowder (V₂AlN, MAX Phase)

Particle Size: 50–100 nm | Purity: >99% | Appearance: Grey to dark-grey nanopowder

1. PRODUCT IDENTIFICATION

Material Name: Vanadium Aluminium Nitride Nanoparticles

Chemical Formula: V₂AlN

Phase Type: MAX Phase (Mₙ₊₁AXₙ)

Appearance / Color: Grey to dark-grey fine nanopowder

Crystal Structure: Hexagonal layered structure

2. TECHNICAL SPECIFICATIONS

Property | Specification |

|---|---|

Chemical Formula | V₂AlN |

Purity | > 99% |

Particle Size | 50–100 nm |

Morphology | Layered, plate-like or nanogranular MAX-phase particles |

Crystal Structure | Hexagonal (P6₃/mmc) |

Density | ~4.3 g/cm³ (typical MAX-phase density) |

Electrical Conductivity | High (metal-like behavior) |

Thermal Conductivity | Good thermal conduction |

Hardness | Moderate (ceramic/metal hybrid) |

Decomposition Stability | >1200°C |

Surface Chemistry | V–Al–N bonding with mixed metallic/covalent character |

Color | Grey to dark-grey |

Storage | Airtight, dry container; protect from moisture |

3. KEY FEATURES

High-purity (>99%) MAX-phase nitride nano-powder

Metallic-like electrical conductivity

Ceramic-like thermal stability and oxidation resistance

Strong mechanical strength & wear resistance

High thermal shock tolerance

Suitable precursor for Nitridic MXene synthesis (V₂NₓTy)

Stable under high-temperature environments

Enhanced surface area for composite reinforcement

4. APPLICATIONS (DETAILED)

A. MXene Synthesis (V₂NₓTᵧ)

Used to produce vanadium nitride-based MXenes

Supports HF/LiF or molten-salt etching routes

Provides 2D conductive nitridic nanosheets

B. High-Temperature Composites

Reinforcement for metal-, ceramic-, and polymer-matrix composites

Aerospace & defense structural components

Thermal barrier coatings

C. Electrical & Energy Applications

EMI shielding systems

Conductive fillers in polymers

Battery electrode additives (Li-ion, Na-ion)

Supercapacitor materials (VN/VC enhanced systems)

D. Catalysis

Active sites suitable for:

HER/OER reactions

Nitrogen fixation

Hydrocarbon reforming

Stable catalyst carrier under harsh conditions

E. Wear-resistant Coatings

Used in protective coatings for industrial tools

High hardness + good conductivity

5. HANDLING & STORAGE

Store in dry, airtight containers

Avoid moisture (may affect surface chemistry)

Use PPE: gloves, goggles, N95/P100 mask

Handle in ventilated/fume hood environment

Keep away from acids, strong oxidizers