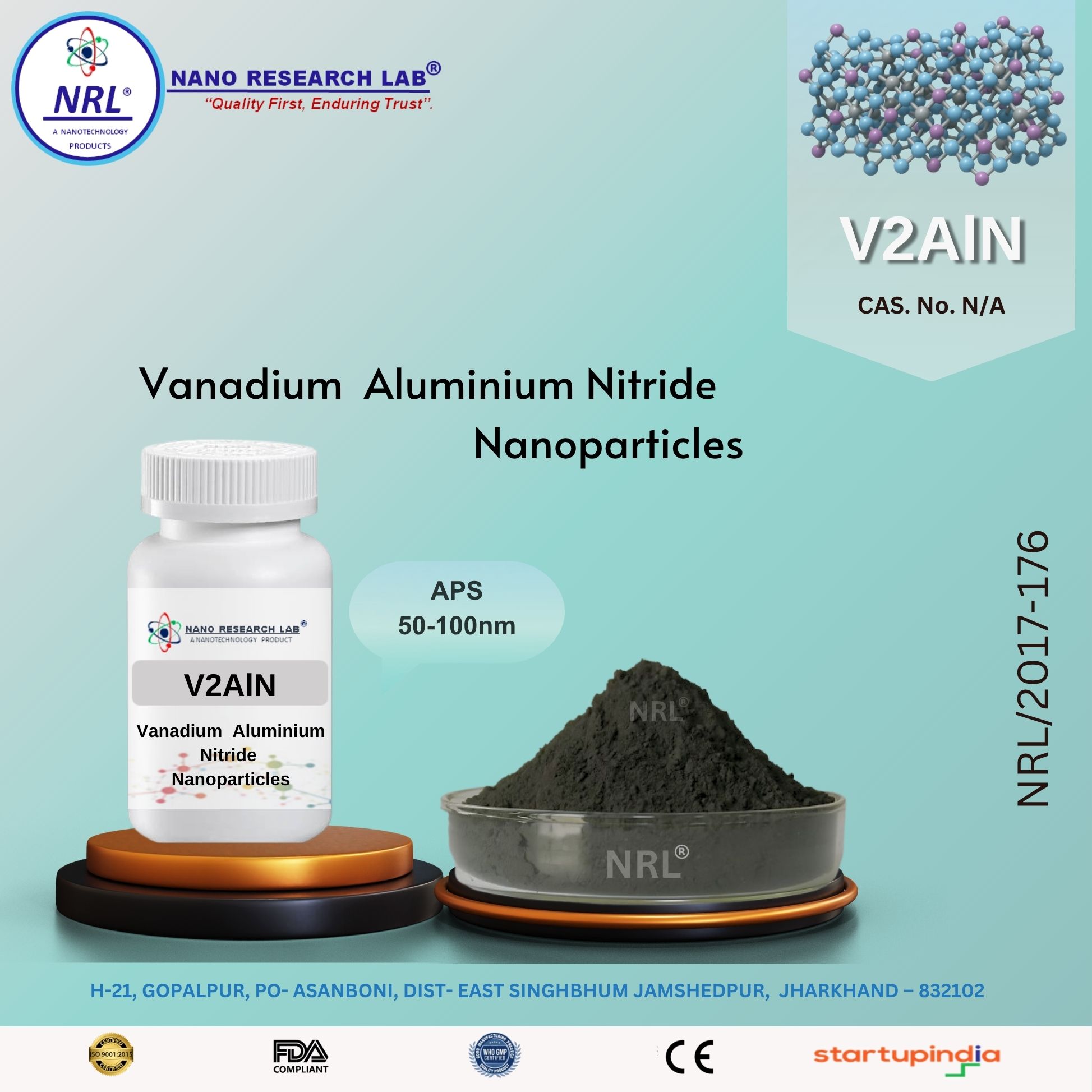

Vanadium aluminium Nitride Nanoparticles / Nanopowder (V2AlN, 50-100nm, Purity: >99%)

₹1475.00

🧪 Vanadium Aluminium Nitride Nanoparticles / Nanopowder (V₂AlN, 50–100 nm, Purity >99%)

⚙️ Technical Specifications

Property | Specification |

|---|---|

Chemical Formula | V₂AlN |

Material Type | MAX Phase precursor (for MXene-type synthesis) |

Purity | >99% |

Average Particle Size | 50–100 nm |

Appearance / Color | Gray to dark-gray fine powder |

Crystal Structure | Hexagonal (MAX Phase) |

Density | ~4.6 g/cm³ |

Melting Point | ~1650 °C |

Hardness | ~5 GPa (Vickers) |

Electrical Conductivity | ~3 × 10⁶ S/m |

Thermal Conductivity | 25–45 W/m·K |

Thermal Expansion Coefficient | ~8 × 10⁻⁶ K⁻¹ |

Elastic Modulus | 330–360 GPa |

Solubility | Insoluble in water and organic solvents |

CAS Number | — (custom laboratory synthesis) |

Storage Conditions | Store in airtight containers under inert atmosphere; protect from moisture and oxidizers |

🌟 Key Features

High-purity (≥99%) Vanadium Aluminium Nitride MAX Phase nanomaterial

Combines metallic conductivity with ceramic strength and stability

Excellent thermal and electrical conductivity

High oxidation resistance and thermal shock tolerance

Stable nanostructure (50–100 nm) enabling uniform dispersion

Superior mechanical performance under extreme conditions

Precursor for MXene-type V₂N-based nanostructures

🔬 Applications

1. Energy Storage & MXene Development

Used as a precursor material for V₂N MXene synthesis

Suitable for supercapacitors, Li-ion, and Na-ion battery electrodes

Offers high specific capacitance and fast ion/electron transport

2. High-Temperature & Structural Materials

Excellent oxidation and thermal resistance for aerospace, turbine, and engine coatings

Retains mechanical integrity at elevated temperatures

3. Electrical & Thermal Conductive Composites

Enhances thermal dissipation and electrical performance in composites

Ideal for conductive polymers, heat sink materials, and thermal interface layers

4. Protective & Anti-Wear Coatings

Provides hard, wear-resistant, and corrosion-resistant coatings

Applied on tools, molds, and high-performance mechanical parts

5. Catalysis & Electrocatalysis

Demonstrates activity in hydrogen evolution reaction (HER) and nitrogen reduction reaction (NRR)

Potential use in electrocatalytic and photocatalytic systems

6. Scientific Research

Used for MXene research, 2D material studies, nanoelectronics, and advanced composites development

⚠️ Handling & Storage

Store in a cool, dry, airtight container under argon or nitrogen atmosphere

Avoid moisture, oxidizing agents, and strong acids

Handle in a fume hood using protective gloves, mask, and eyewear

Prevent dust formation and inhalation of fine particles

Keep away from heat, sparks, and direct sunlight