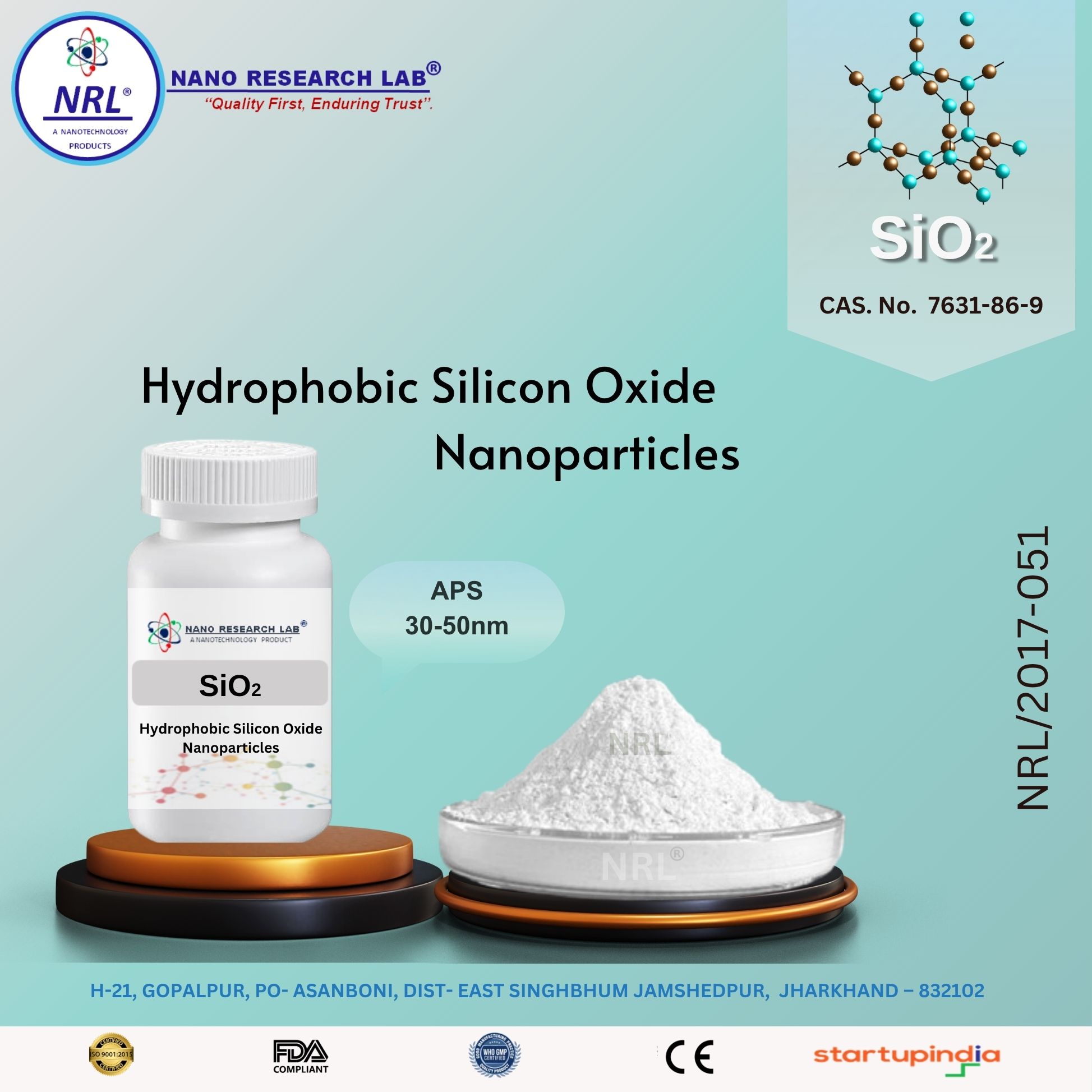

Silicon Oxide Nanoparticles/Nanopowder Hydrophobic (SiO2, 30-50nm, purity 99.5%)

₹1475.00

Hydrophobic Silicon Dioxide Nanoparticles / Nanopowder (SiO₂, 30–50 nm, Purity 99.5%)

Technical Specifications

Property | Specification |

|---|---|

Chemical Name | Silicon Dioxide (SiO₂, Hydrophobic) |

CAS Number | 7631-86-9 |

Molecular Weight | 60.08 g/mol |

Purity | ≥ 99.5% |

Appearance / Color | White Fine Powder |

Particle Size (Average) | 30–50 nm |

Morphology | Nearly Spherical / Agglomerated Nanoparticles |

Surface Property | Hydrophobic (Surface-treated) |

Specific Surface Area (BET) | 120–160 m²/g |

Density | 2.2 g/cm³ |

Melting Point | 1710 °C |

Boiling Point | Sublimes above 2230 °C |

Solubility | Insoluble in water; soluble in hydrofluoric acid |

pH (in aqueous suspension) | ~5–7 |

Stability | Chemically stable; non-hygroscopic under normal conditions |

Key Features

High Purity (≥ 99.5%) ensures excellent chemical and physical performance.

Nanoscale Particle Size (30–50 nm): Provides high surface area and excellent dispersion properties.

Hydrophobic Surface: Modified for water repellency and improved compatibility with non-polar systems.

Spherical Morphology: Promotes uniform dispersion in polymers, liquids, and composites.

White Fine Powder: Easy to handle, mix, and incorporate into formulations.

Thermally Stable: Suitable for high-temperature and electronic applications.

Enhanced Surface Reactivity: Surface-treated for specific applications in coatings and composites.

Applications

1. Hydrophobic Coatings & Paints:

Used in water-repellent coatings, paints, and varnishes to improve surface properties.

2. Polymer & Nanocomposites:

Enhances mechanical properties, thermal stability, and hydrophobicity in polymer formulations.

3. Electronics & Insulation:

Applied in dielectric materials, electronic coatings, and hydrophobic insulation layers.

4. Cosmetics & Personal Care:

Used as a matting agent, anti-caking agent, and texture enhancer in hydrophobic formulations.

5. Silicone & Rubber Applications:

Acts as a reinforcing filler in silicone, rubber, and elastomers to improve water resistance and mechanical properties.

6. Research & Nanotechnology:

Suitable for hydrophobic nanocomposite studies, advanced material research, and functional coatings.