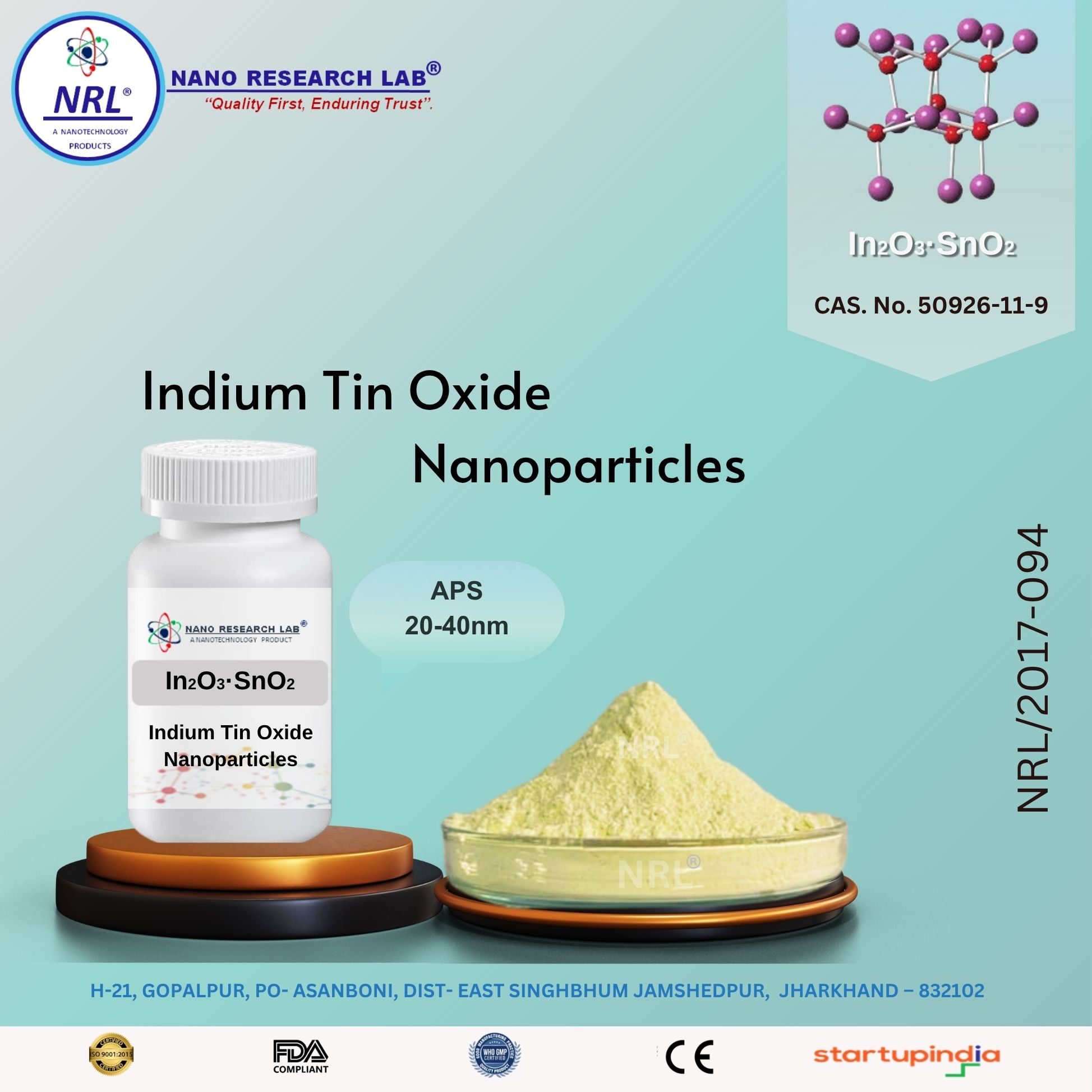

Indium Tin Oxide Nanoparticles/Nanopowder (In2O3:SnO2=90:10Wt%, 20-40nm, purity 99.5%)

₹2900.00

Indium Tin Oxide Nanoparticles / Nanopowder (In₂O₃:SnO₂ = 90:10 wt%, 20–40 nm, Purity 99.5%)

⚙️ Technical Specifications

Property | Specification |

|---|---|

Product Name | Indium Tin Oxide (ITO) Nanoparticles / Nanopowder |

Chemical Formula | In₂O₃:SnO₂ = 90:10 wt% |

Purity | ≥ 99.5% |

Average Particle Size (APS) | 20–40 nm |

Appearance | Yellowish-white fine powder |

Crystal Structure | Cubic (In₂O₃), Rutile (SnO₂ doped) |

Density | ~7.1 g/cm³ |

Electrical Conductivity | Conductive, resistivity ~10⁻⁴–10⁻³ Ω·cm (depending on sintering) |

Transparency | High optical transparency in visible range |

Solubility | Insoluble in water; stable under ambient conditions |

CAS Number | 12068-37-6 (In₂O₃) |

🌟 Key Features

High-purity (99.5%) ITO nanoparticles with 20–40 nm particle size

Excellent electrical conductivity and optical transparency

High surface area for thin-film and coating applications

Thermally and chemically stable

Non-toxic and suitable for electronics, optoelectronics, and research applications

🔬 Applications (in Detail)

1. Transparent Conductive Films

Used in touchscreens, LCDs, OLED displays, and photovoltaics

Provides high conductivity while maintaining optical transparency

2. Sensors & Electronics

Utilized in gas sensors, electrochromic devices, and MEMS/NEMS applications

High surface area nanoparticles improve sensitivity and response time

3. Coatings & Thin Films

Suitable for sputtering, screen-printing, and sol-gel deposition

Forms uniform, conductive, and transparent coatings on glass and polymer substrates

4. Catalysis

Acts as a catalyst or catalyst support in chemical reactions and fuel cell electrodes

Nanoparticles enhance surface reactivity and electron transfer

5. Research & Nanotechnology

Ideal for optoelectronics, conductive coatings, and nanomaterial studies

Enables functionalization for hybrid materials and composites

⚠️ Handling & Storage

Store in a sealed, dry container, away from moisture and strong acids

Handle with gloves, mask, and eye protection to prevent nanoparticle inhalation

Stable under ambient and laboratory conditions

Avoid prolonged exposure to high temperatures beyond decomposition point