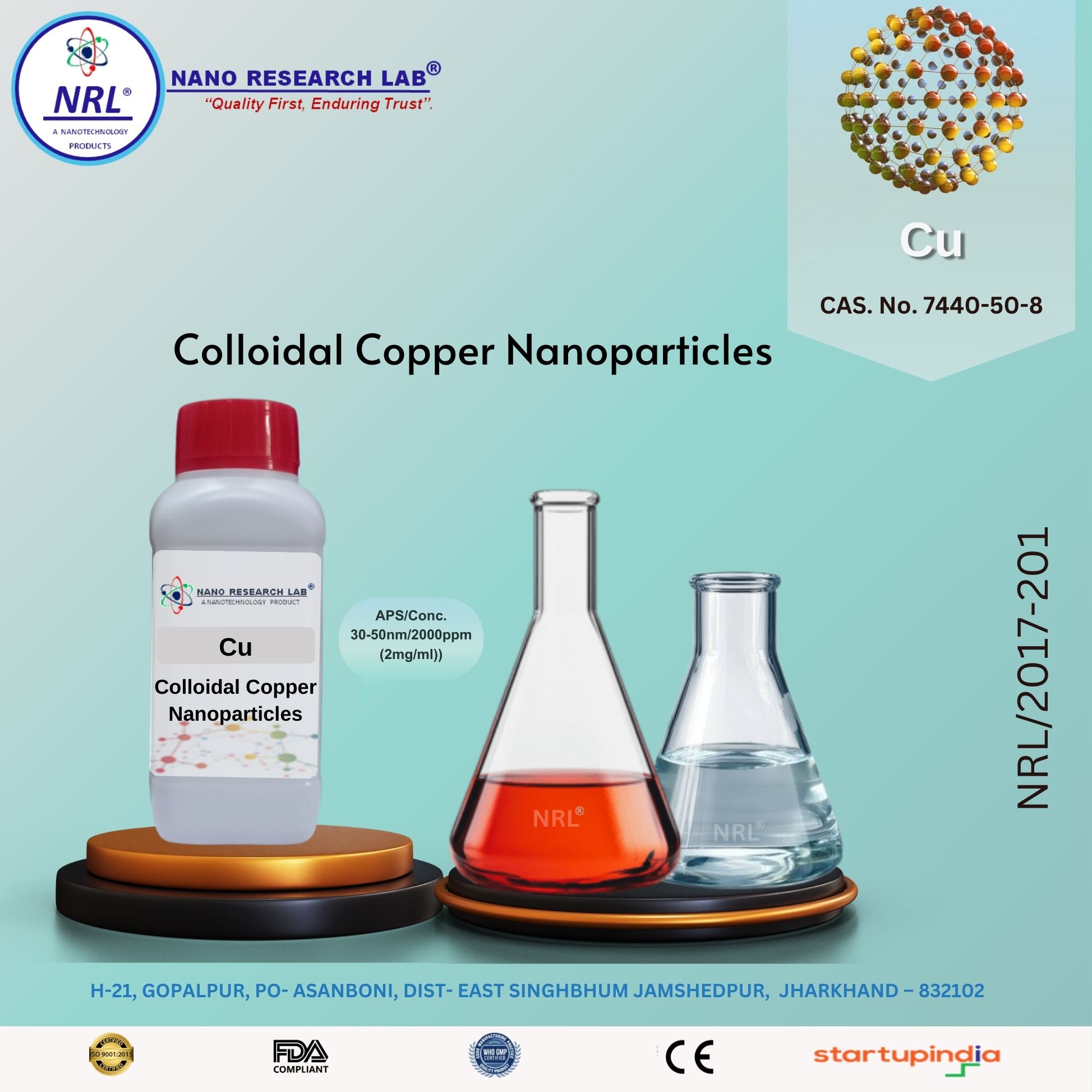

Colloidal Copper Nanoparticles (Cu, 2000ppm, Purity 99%, 30-50nm)

₹2714.00

🧪 Colloidal Copper Nanoparticles (Cu, Purity 99%, 30–50 nm, 2000 ppm / 2 mg/mL)

⚙️ Technical Specifications

Property | Specification |

|---|---|

Material Name | Colloidal Copper Nanoparticles |

Chemical Formula | Cu |

Purity | 99% |

Particle Size | 30–50 nm |

Concentration | 2000 ppm (2 mg/mL) |

Appearance / Color | Reddish-brown transparent colloidal solution |

Solvent | Deionized water or ethanol (depending on preparation) |

Surface Charge (Zeta Potential) | Typically -30 to -40 mV |

Stability | Stable for 6–12 months under proper storage conditions |

pH | 6–8 |

CAS Number | 7440-50-8 |

Storage Conditions | Store in dark, airtight container at room temperature; avoid direct sunlight, heat, and strong oxidizers |

🌟 Key Features

High-purity copper nanoparticles (30–50 nm)

Stable aqueous colloidal solution (2000 ppm / 2 mg/mL)

Uniform particle size ensures consistent performance

High surface area enhances conductivity, catalytic, and antimicrobial properties

Biocompatible and environmentally friendly

Versatile for electronics, catalysis, coatings, and research applications

🔬 Applications

1. Electronics & Conductive Materials

Used in conductive inks, printed electronics, and nanocomposites

Enhances electrical and thermal conductivity

2. Catalysis

Acts as catalyst or catalyst support in chemical and electrochemical reactions

3. Medical & Antimicrobial

Applied in antimicrobial coatings, wound care, and hygiene products

4. Nanocomposites & Coatings

Incorporated into polymers, ceramics, and hybrid materials for improved mechanical, thermal, and conductive properties

5. Research & Material Science

Ideal for nanotechnology, biosensors, and material engineering studies

⚠️ Handling & Storage

Store in a dark, airtight container away from sunlight and heat

Avoid contact with strong acids, bases, and oxidizing agents

Handle with gloves, protective eyewear, and lab coat

Use in well-ventilated areas

Shake gently before use to ensure uniform dispersion