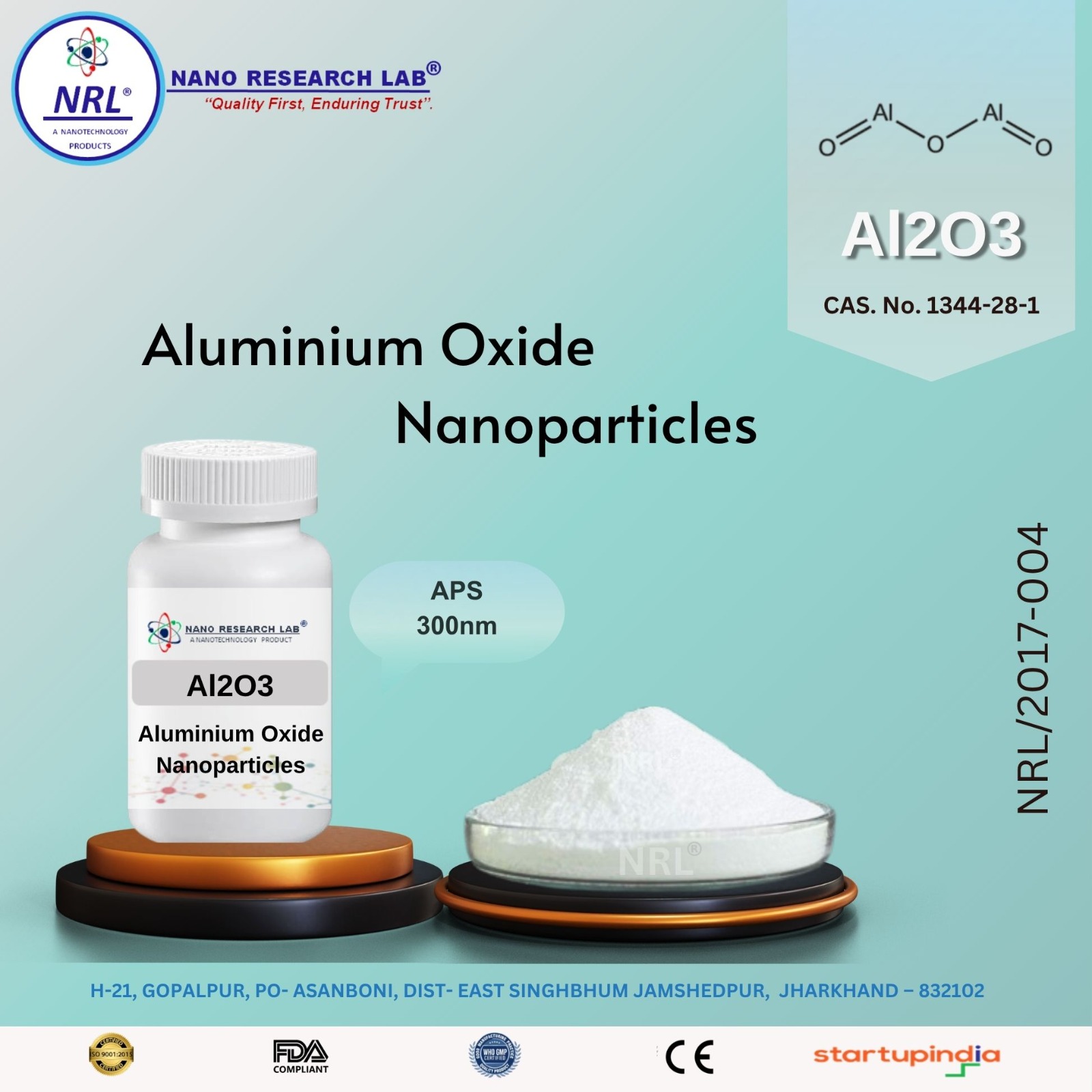

Aluminium oxide Nanoparticles/Nanopowder (Al2O3, Alpha, 300nm, purity 99.5%)

₹1475.00

🧪 Aluminium Oxide Nanoparticles / Nanopowder (Al₂O₃, Alpha)

Particle Size: ~300 nm

Purity: 99.5%

⚙️ Technical Specifications

Property | Specification |

|---|---|

Material Name | Aluminium Oxide Nanoparticles / Nanopowder |

Chemical Formula | Al₂O₃ |

Purity | 99.5% |

Particle Size | ~300 nm |

Appearance / Color | White fine powder |

Phase / Structure | Alpha (α-phase) |

Crystal Structure | Hexagonal / Rhombohedral (Corundum) |

Specific Surface Area (SSA) | 10–20 m²/g |

True Density | 3.97–4.0 g/cm³ |

Bulk Density | 0.4–0.8 g/cm³ |

Melting Point | ~2040 °C |

Boiling Point | ~2980 °C |

Solubility | Insoluble in water; soluble in strong acids and alkalis |

pH (5% dispersion) | 5–9 |

CAS Number | 1344-28-1 |

Storage Conditions | Store in a dry, airtight container away from moisture and strong acids/bases |

🌟 Key Features

High-purity (99.5%) alpha-phase Al₂O₃ nanoparticles with stable crystalline structure

Medium particle size (~300 nm) for balanced surface area and dispersion behavior

Excellent thermal, mechanical, and chemical stability for demanding applications

High hardness (Mohs 9) and superior wear resistance

Chemically inert, corrosion-resistant, and non-reactive under most conditions

Electrical insulator with high thermal conductivity

Suitable for ceramic, refractory, coating, and composite applications

🔬 Applications (Detailed)

1. Advanced Ceramics & Refractory Materials

Used in high-strength ceramics, crucibles, and thermal components

Enhances mechanical durability, abrasion resistance, and temperature tolerance

2. Coatings & Surface Protection

Ideal for thermal barrier coatings, anti-corrosion coatings, and refractory linings

Provides heat insulation and oxidation resistance in high-temperature environments

3. Composite Reinforcement

Improves stiffness, hardness, and dimensional stability of metal–ceramic and polymer–ceramic composites

Enhances thermal shock resistance and mechanical strength

4. Catalysis & Support Materials

Serves as a stable catalyst support for high-temperature reactions

Maintains structural integrity and surface activity during catalytic cycles

5. Polishing & Abrasives

Used in fine polishing, lapping, and abrasive applications for metals, optics, and semiconductors

Provides consistent surface finish with high wear resistance

6. Electronics & Dielectrics

Functions as a highly insulating dielectric material

Applied in capacitors, substrates, and protective coatings in electronics manufacturing

⚠️ Handling & Storage

Store in a cool, dry, and sealed container

Keep away from moisture, acids, and alkalis

Handle with protective gloves, goggles, and lab coat

Avoid inhalation of fine powder; use under fume hood or ventilated area

Prevent contamination during use and storage